Review on vertical roller mill in cement industry its

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and

learn more

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials. With the grinding capacity of a vertical roller

learn more

A cement Vertical Roller Mill modeling based on the

2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and

learn more

Vertical Roller Mills - FLSmidth

Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or

learn more

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2022年7月26日 The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate -

learn more

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from... Find, read and cite all the...

learn more

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process

learn more

Modeling of energy consumption factors for an industrial cement ...

2022年5月9日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored operational

learn more

quadropol® vertical roller mill - thyssenkrupp

quadropol® vertical roller mill thyssenkrupp is one of the few full-range suppliers for the cement industry – from individual machines, all the way up to complete cement plants, and this since decades. The market

learn more

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power

learn more

Modeling of energy consumption factors for an industrial cement ...

2022年5月9日 The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill). The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2. ...

learn more

quadropol® vertical roller mill - thyssenkrupp

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process. Mombasa Cement Ltd.

learn more

Indicate Contributions from Several Radial

The study and research was conducted in a cement industry where Vertical roller mill was employed in cement grinding section. In this case problem was, Cement Mill was not performing as per its design parameters. It was a Vertical Roller Mill is designed for rated capacity 215 TPH but its

learn more

Analysis and Optimization of Grinding Performance of Vertical Roller ...

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

learn more

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 Keywords: Vertical roller mill, cement grinding, performance evaluation . INTRODUCTION. Cement production is highly energy consuming process . with energy utilization of around 110-150 kWh/t (Villa,

learn more

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022年4月6日 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill.The largest grain mills used worked a ...

learn more

Review on vertical roller mill in cement industry its

2021年1月1日 A cement Vertical Roller Mill modeling based on the number of breakages. 2022, Advanced Powder Technology. Citation Excerpt : The material layer generated between the roller and the revolving table is the grinding bed. The grinding bed is the fundamental factor in the proper operation of a VRM, as defined by the feed size, feed

learn more

A cement Vertical Roller Mill modeling based on the

2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and nonmetallic ore industries. For the sectors above, the VRM is a powerful and energy-intensive grinding field [1], [2]. It is used to grind slag, nonmetallic ore, and other block

learn more

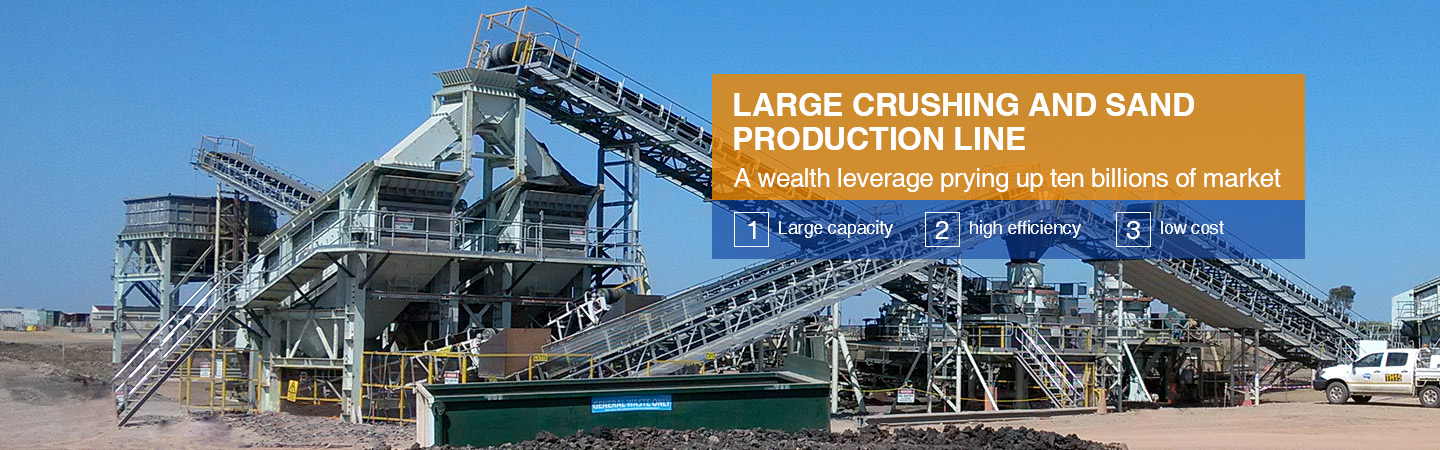

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading

learn more

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding ...

learn more

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane

learn more

Gear units to fit your vertical roller mill FLSmidth

Our comprehensive line of gear for vertical roller mills excels in many applications, including coal or raw material comminution and cement grinding. With power output ranging from a few 100kW to over 10MW, we have the drive solutions and gear units to meet your needs – and optimise your production. Products. Services.

learn more

OK™ cement mill The most energy- efficient mill for

2019年4月10日 OK™ cement mill - FLSmidthIf you are looking for a reliable and efficient cement grinding solution, you may want to consider the OK™ cement mill. This brochure introduces you to the features and benefits of this vertical roller mill, which can handle a wide range of cement types and capacities. Learn how the OK™ cement mill can help you

learn more

Gebr. Pfeiffer

Pfeiffer (India) Pvt. Ltd. received an order for the delivery of several grinding plants with vertical roller mills for grinding cement raw material as well as solid fuels. read more. 19-10-2022. Gebr. Pfeiffer wins new cement customer in India: 350 t/h cement mill for Udaipur Cement Works Ltd.

learn more

Vertical Roller Mill - PROSES PRODUKSI DI AREA ...

PROSES PRODUKSI DI AREA CEMENT MILL. IV. 2. Vertical Roller Mill. Prinsip kerja vertical roller mill adalah klinker digiling diatas rotating table oleh 3 (tiga) buah roller. Roller ini menekan klinker dengan tekanan hydraulic. system 60 – 80 bar. Material yang telah digiling turun dari grinding table dan.

learn more

Cement grinding Vertical roller mills VS ball mills

However, the unit cost for wear parts for a ball mill is much lower than for a vertical roller mill. For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement.

learn more

Comparing ball mills and VRMS for cement grinding

2013年2月26日 Ball mills are built at the supplier’s factory and transported to the cement producer’s site. In contrast, the vertical mill is built onsite at the cement plant, avoiding difficult logistical issues and associated costs. The equipment costs are higher for a VRM than a ball mill, reflecting the greater complexity of the system, which ...

learn more

Comparison Of Cement Vertical Roller Mill And Roller Press

When grinding raw meal, the unit power consumption of the vertical roller mill and the roller press is about the same, which is 7-8kWh/t. But the vertical mill is usually slightly higher. The system of the vertical grinding mill is simple and stable. It has ideal adaptability to material moisture and can achieve the goal of energy saving on the ...

learn more

Cement Finish Milling (Part 1: Introduction History)

2019年12月2日 Although ball mills were first introduced in the 1860’s, the main progress was made during the 1870’s to 1900’s in Germany, where its growing cement and chemical industries increased the ...

learn more

(PDF) Drives for large vertical roller mills - ResearchGate

2017年1月1日 Jan 2016. 41-48. M Keyßner. T Fahrland. Keyßner, M. and Fahrland, T.: Drive selection for large Loesche vertical roller mills. Cement International, 2/2016, pp. 41-48. Operational experience ...

learn more